Understanding HDPE Plastic and Its Role in Geosynthetic Systems

What Is HDPE Plastic and Why It's Ideal for Geosynthetics

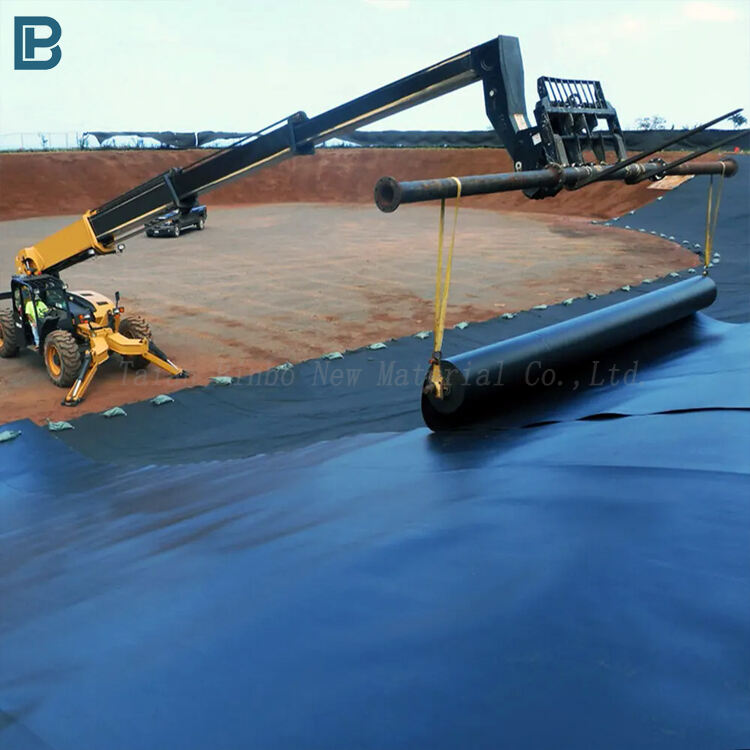

High density polyethylene, or HDPE for short, stands out among thermoplastics because it combines impressive strength with relatively low weight. Plus, it resists chemicals pretty well and lasts a long time under various conditions. The material typically has a density between 0.940 and 0.965 grams per cubic centimeter, which makes it great at creating watertight barriers needed in things like landfills and water storage systems. Compared to older options such as clay or concrete, HDPE membranes block almost all liquid passage at around 99.9% effectiveness while still being flexible enough to handle ground movements without cracking. A recent look at industry numbers from 2024 shows that about six out of ten geomembrane projects worldwide use HDPE these days. This popularity comes down to both wallet-friendly pricing and meeting those important ASTM and ISO quality standards that many clients demand.

Rising Demand for HDPE Geomembranes in Infrastructure Development

According to MarketsandMarkets data from 2024, the worldwide geomembrane market stands at around $2.3 billion right now and should see annual growth of about 5.4% all the way through 2030. Urban expansion and increasingly strict environmental laws are pushing this growth forward. High density polyethylene (HDPE) has become king of the hill when it comes to big infrastructure work. Take landfills for instance - roughly seven out of ten modern facilities install HDPE liners to stop harmful leachate from escaping into groundwater. Mining operations and wastewater treatment plants also depend heavily on HDPE because it resists chemicals so well, making it ideal for containing potentially dangerous substances. Even regulatory bodies such as the Environmental Protection Agency acknowledge how well HDPE performs under tough conditions, often mentioning that these materials can last over half a century before needing replacement.

Advantages of HDPE Over Traditional Containment Materials

HDPE outperforms alternatives such as PVC and compacted clay in three key areas:

- Chemical resistance: Resists over 1,500 industrial chemicals, including acids and hydrocarbons (ASTM D5397 testing).

- Longevity: Maintains integrity under UV exposure and temperature extremes from -60°C to 80°C.

- Installation efficiency: Weighs 85% less than concrete, reducing transportation and labor costs by up to 40%.

A 2023 study by the Geosynthetic Institute found that HDPE-lined waste ponds reduce leakage risks by 92% compared to clay systems, reinforcing its role as a sustainable engineering solution.

Core Properties of HDPE Geomembranes That Ensure Reliability

Exceptional Chemical Resistance and Environmental Protection

HDPE geomembranes can stand up against over 300 different industrial chemicals, from strong acids across the pH spectrum (1 to 14) right through to hydrocarbons and even those pesky chlorinated solvents. Tests conducted back in 2023 by EPA researchers found absolutely no signs of wear or breakdown after these materials spent 10,000 long hours exposed to harsh landfill leachate conditions. What makes this so important? Well, in places where contamination really matters, such as those massive mining effluent ponds, HDPE actually cuts down on heavy metal migration by nearly 99.8% when compared with traditional clay barriers. That kind of performance difference explains why so many environmental engineers prefer HDPE for their containment solutions.

Long-Term Durability and Performance in Harsh Conditions

Accelerated aging tests at Michigan State University (2023) show HDPE retains 95% of tensile strength after 50 years under UV exposure. Key performance attributes include:

- UV Resistance: Carbon-black stabilized sheets last over 25 years in direct sunlight

- Thermal Stability: Operates effectively between -60°C and 80°C without warping or embrittlement

- Puncture Resistance: Offers 3.5 times greater tear strength than PVC membranes (ASTM D1004)

Low Permeability and Superior Water Containment Capabilities

With permeability coefficients below 1×10⁻¹³ cm/s (ASTM D5886), HDPE excels in hydraulic containment:

| Material | Permeability (cm/s) | Chemical Degradation Risk |

|---|---|---|

| Material | Permeability (cm/s) | Chemical Degradation Risk |

| HDPE | ≤1×10⁻¹³ | Low |

| PVC | 1×10⁻⁸ | High |

| PVC | 1×10⁻⁷ | Moderate |

This ultra-low permeability helps prevent an estimated 740 million liters of annual water loss in agricultural reservoirs (ASTM D5886).

Additionally, HDPE’s elongation capacity of up to 700% (ASTM D6693) allows it to conform seamlessly to uneven surfaces and seismic zones. A 2023 study found HDPE had successful installation on 147 different mining containment setups with 5-meter elevation changes, achieving leakage rates as low as 0.02% using custom-textured liners.

Case Study: HDPE Implementation in a Municipal Landfill Success Story

The $4.2 million project to implement HDPE liners at a municipal landfill led to significant improvements:

| Metric | Pre-HDPE (2018) | Post-HDPE (2023) |

|---|---|---|

| Leachate containment breaches | 14/year | 1/year |

| Groundwater remediation costs | $2.1M/year | $2.0M/year |

| Groundwater remediation costs | $2.1M/year | $0.7M/year |

The project achieved a full return on investment within 3.2 years through reduced penalties and operational savings.

HDPE Membrane Thickness and Surface Texture Options

The thickness of HDPE geomembranes typically falls between 0.5 millimeters and above to ensure durability against stress and weather impact. For landfills, thicker options are chosen as they withstand better against external pressures over time, and surface texturing significantly increases friction for slope stability. Smooth HDPE membranes remain popular in completely welded systems like wastewater tanks where seam strength is crucial.

Smooth vs. Textured HDPE: Impact on Friction and Slope Stability

According to lab shear tests following ASTM D5321, textured HDPE surfaces achieve higher friction coefficients compared to smooth surfaces when combined with geotextiles. These coefficients range between 0.6 to 1.0 for textured HDPE and around 0.3 to 0.5 for smooth HDPE, highlighting a significant advantage in friction and slope stability.

Compliance with ASTM, ISO, and GRI-GM13 Quality Standards

Compliance with industry standards such as ASTM, ISO, and GRI-GM13 ensures HDPE materials are highly durable and perform well under rigorous environmental conditions. Regular testing and updates in standards contribute to the ongoing reliability of these materials. Projects utilizing certified HDPE materials demonstrate failure rates of less than 5% annually when contain waste leakage and endure under severe conditions.

FAQ Section

What is HDPE plastic used for?

HDPE plastic is commonly used in geosynthetic systems for its impressive strength, chemical resistance, and durability under a wide range of conditions. It’s primarily used in applications such as landfills, water storage systems, mining operations, and wastewater treatment plants.

What makes HDPE an ideal material for geomembranes in environmental projects?

HDPE’s exceptional chemical resistance, long-term durability, the ability to perform under UV exposure, and its low permeability make it an ideal material for environmental projects. It is effective in preventing leaks from landfills and containing hazardous materials in mining and wastewater treatment facilities.

How does HDPE compare to traditional containment materials like PVC or compacted clay?

Compared to PVC and compacted clay, HDPE provides superior chemical resistance, longer-lasting durability under UV exposure, and greater installation efficiency due to its lighter weight, which significantly reduces transportation and labor costs.

What are the compliance standards for HDPE materials used in projects?

HDPE materials used in geosynthetic systems are generally compliant with industry standards such as ASTM, ISO, and GRI-GM13. These standards ensure the materials’ durability, chemical resistance, and performance in harsh conditions.

Table of Contents

- Understanding HDPE Plastic and Its Role in Geosynthetic Systems

-

Core Properties of HDPE Geomembranes That Ensure Reliability

- Exceptional Chemical Resistance and Environmental Protection

- Long-Term Durability and Performance in Harsh Conditions

- Low Permeability and Superior Water Containment Capabilities

- Case Study: HDPE Implementation in a Municipal Landfill Success Story

- HDPE Membrane Thickness and Surface Texture Options

- Smooth vs. Textured HDPE: Impact on Friction and Slope Stability

- Compliance with ASTM, ISO, and GRI-GM13 Quality Standards

- FAQ Section